EQUIPMENT INSTALLATION

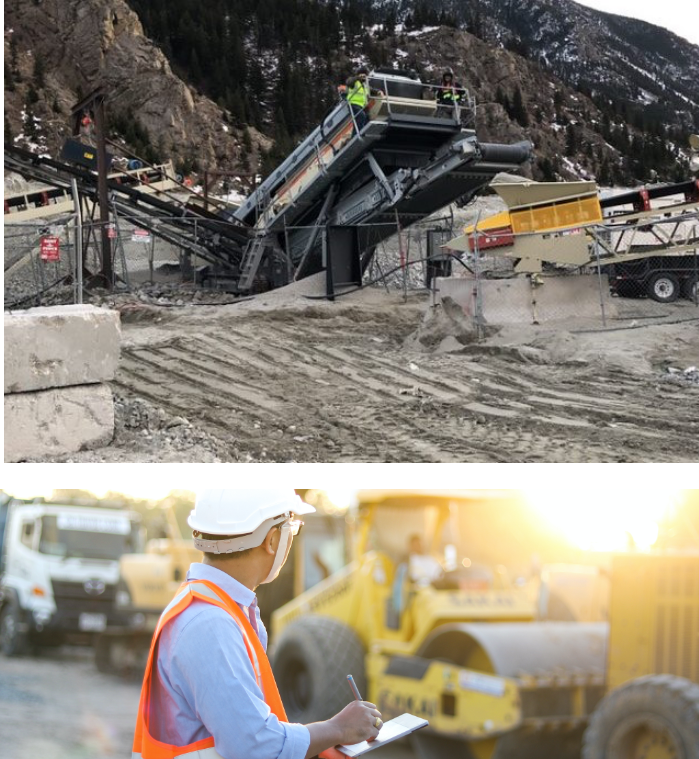

Precision, alignment, and extreme attention to detail are why we excel in equipment installation and integration. We understand the requirements for equipment installation from both a high-level perspective and very detailed level of execution.

SEAMLESS INTEGRATION

We utilize roto aligns, precision milling, and precision surveying to ensure accurate installation and integration. From small pumps and motors to large filter presses, ball mills, and crushers Capra’s equipment integration is seamless.

WORK WITH USROBUST QA/QC PROCEDURES

Our robust quality assurance and control procedures ensure manufacture installation specifications are followed precisely. The result? Seamless startup, lasting equipment longevity, and maximum equipment efficiency.

RELEVANT INDUSTRIES

CONTACT US

We provide you with unrivaled construction services. Are you ready to request a bid for your next project? Let’s get started.

GET IN TOUCH